Automatic

tire deflators are designed to open to discharge air when tire pressure is

higher than preset psi, and close when the tire pressure drops to preset psi. Although,

there are many kinds of tire deflator which look quite different, they work in

the same way.

The Struction of automatic tire deflators:

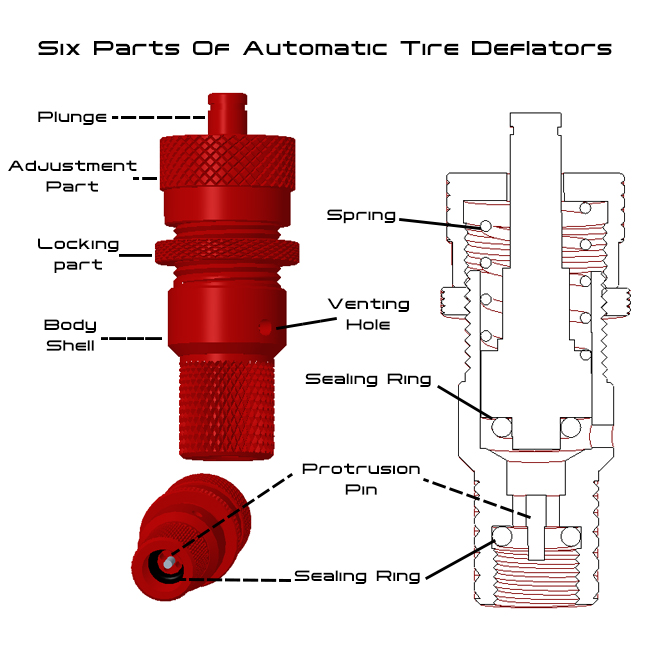

Different types of automatic tire deflators may have different structures. But they at least have 6 parts to achieve the function.

1. Body shell with venting hole to hold all parts.

2. A feature to connect to the valve stem including a protrusion pin and a sealing ring. This feature can be designed on the body shell as a whole, or made as a separate part.

3. A plunger with sealing oring which can move up (Open) and down (Close) in the body shell.

4. Spring which provide adjustable force.

5. Adjustment part which can compress and relief the spring

6. Locking part which can lock the position of the adjustment part

How they work?

Let’s define following parameters:

1. P0 = Initial tire pressure

2. P1 = Real time pressure

3. P2 =Preset pressure of the deflator (the pressure is provided by spring)

Assuming that the initial tire pressure P0=40 psi and we has already preset the deflator to P2=20psi.

When not connect to the valve stem, P1=0. So P1<P2, deflator will close due to the spring force.

When connect to the valve stem, P1=P0=40psi. So P1>P2(P2=20psi), the plunge will be pushed up by tire pressure. The air will flow out and simutaniously, tire pressure drops down. When the tire pressure drops to 20 psi, the plunge will be pushed down and seal by the spring again.